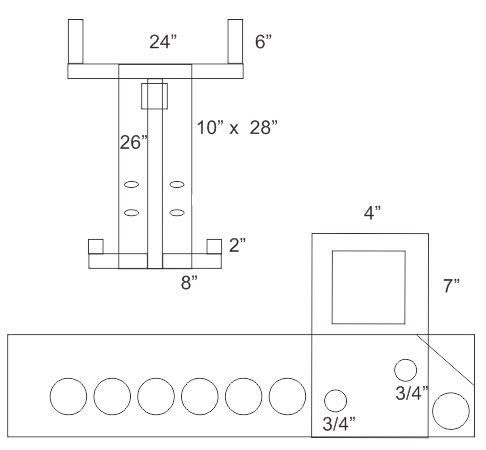

Below shows drawing of frame for tube bender roll stand.

The

drawing, above is for a roll around pipe bender stand. The top drawing

is of the frame. Made from 2" x 2" 120 wall. For a little more balance, I moved

the front casters forward, with a pair of rear casters. The hydraulic pump mounting plate is 3/16 plate,

slotted holes for 3/8" bolt on pump mounting. Now the roughest part was the

mounting plate for bender. To start with, I had no idea how the bender bolted to plate. I looked at some YouTube videos and figured it out?

Above is the frame. Found 150 lb casters and using rubber blocks for

hydraulic pump mounting.

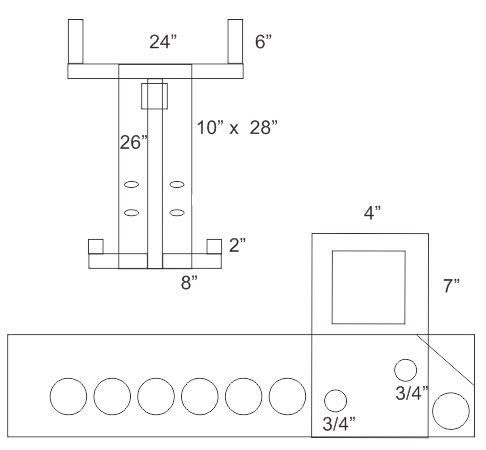

Above is the

pedestal and hydraulic pump mounting plate. The pedestal is cut from 2 1/2" x 2

1/2" 3/16 wall, square tubing. The top plate is 1/2" plate. Top plate was cut with

PM45, even tried my luck cutting holes. You can see the pump mounting plate

will over laps "T" in front and rear frame (in drawing), that will

help reinforce frame. It also extends 1/2" beyond

pump assembly for bump protection, 8" wide. I reversed the pump on the stand, to

protect the hydraulic reservoir and make the power cord on the pump motor reach

the wall better.

Finished ???

The design above failed (new drawing above). I had it painted, with hydraulic

pump, and bender installed with die and cylinder. I tried to push the stand wide ways a

little, the whole stand started to tip over, bad design.

I tore the stand

apart this morning, for the tipping problem. The remedy, a

rear "T", with dual not single casters. You can see the pump mounting

rubber blocks and mounting bolts. The metals all cut. need to welded up now.

This might stop it

from tipping over.

This is the

finished stand. It works great, no tipping now. Sorry about the shadow.